Fiberglass Reinforced Epoxy (FRE) is a strong and versatile material with numerous applications. It is used in everything from construction to engineering, and its properties make it ideal for many projects.

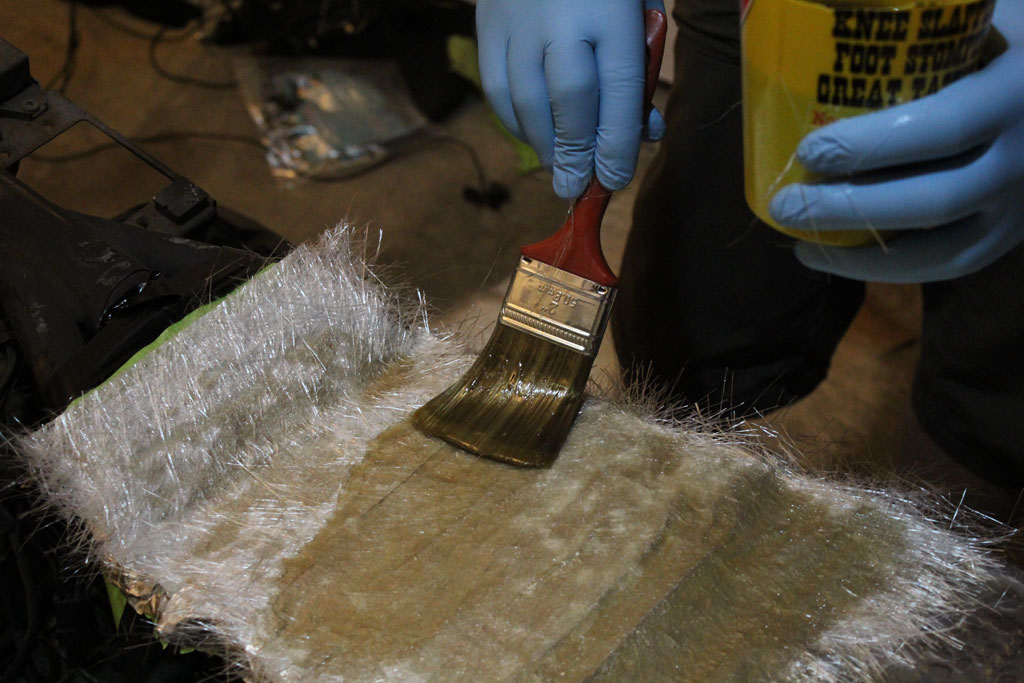

FRE combines the strength of fiberglass with the durability of epoxy resin, making it an incredibly reliable option that can be relied upon in even the most demanding conditions. Its flexibility allows FRE to be shaped into different forms and shapes which makes it ideal for intricate designs where precision is key.

Additionally, FRE stands up well against corrosion and weathering without losing any of its strength or form over time. This makes it perfect for outdoor structures and other applications exposed to harsh elements.

The advantages of using Fiberglass Reinforced Epoxy are clear: its strength gives peace of mind when used in critical situations, while its versatility allows for creative uses across a variety of different industries.

Superior Strength and Durability

Fiberglass Reinforced Epoxy (FRE) is a strong and versatile material, capable of withstanding extreme temperatures, pressures and other harsh environmental conditions. With superior strength and durability, FRE is the perfect choice for numerous applications ranging from industrial use to consumer goods.

Its resilient nature makes it ideal for constructing items that must be able to withstand long-term exposure to weathering or abuse without compromising its structural integrity. In addition to being incredibly durable, FRE also offers excellent mechanical properties such as high tensile strength and impact resistance.

This means that it can easily handle heavy loads without breaking or cracking under pressure. It also has great thermal insulation properties which make it suitable for various applications where heat retention is necessary such as in electronics manufacturing or automotive engine components. Not only does this provide an increased level of safety but it also helps reduce energy costs significantly over time by keeping the temperature within tolerable levels.

Whats more, FRE is a lightweight material yet still provides an impressive level of rigidity due to its polymer composition structure which gives it greater stability against flexing forces than many other materials available on the market today. As well as requiring less raw materials during production when compared with traditional metals like steel or aluminum, making fiberglass reinforced epoxy an extremely cost-effective choice for a variety of projects with little compromise on quality or performance requirements

Lightweight yet Robust Design

Fiberglass reinforced epoxy is known for its lightweight yet robust design, making it a popular choice among many industries. This versatile material offers tremendous strength for various applications and works well in extreme temperatures.

It can be molded into any shape with ease, allowing you to create intricate designs without compromising on structure or integrity. The combination of glass fibers and resin creates an incredibly strong composite that can withstand heavy loads while still being relatively lightweight compared to other materials commonly used in the industry. Its high tensile strength makes fiberglass reinforced epoxy perfect for structural components and load-bearing elements, as well as products requiring superior durability such as boats, furniture, aircraft parts and more.

Furthermore, this material is highly corrosion resistant which means that it will last longer than traditional metals even when exposed to harsh environments and chemicals. Thanks to its versatility and dependability, fiberglass reinforced epoxy has become a go-to solution for many projects due its reliable performance time after time.

Versatility for a Variety of Applications

Fiberglass reinforced epoxy (FRE) is a strong and versatile material that can be used in a wide variety of applications. Its exceptional strength, durability, and low cost make it ideal for many types of projects.

Its also lightweight yet still provides excellent protection from the elements. FRE offers superior resistance to corrosion and abrasion compared to other materials which makes it an ideal choice for outdoor structures such as docks, decks, ladders, or fences.

Additionally, FRE is incredibly flexible and can easily be molded into any shape desired making it suitable for complex projects like sculptures or architectural designs. With its versatility it can also be used in industrial fabrication processes such as welding or painting operations where its high-performance properties are invaluable assets.

Whatever project you decide to undertake with fiberglass reinforced epoxy you’re sure to find that this incredible material has the strength and flexibility necessary for success!

Conclusion

Fiberglass reinforced epoxy is an increasingly popular material choice due to its strength and versatility. It has a wide range of applications, from boat hulls to wind turbine blades, because of its ability to resist corrosion and fatigue in extreme conditions.

Its properties make it the perfect material for a variety of projects requiring strong yet lightweight components. Whether utilized as part of a larger product or as standalone parts, fiberglass reinforced epoxy can consistently provide superior performance compared to alternative materials.