The 300W Laser Welder Machine has revolutionized the way precision welding is done. It offers powerful performance and unparalleled accuracy, allowing users to harness its capabilities with ease.

With a sleek design and advanced technology, this machine can tackle any welding job you throw at it. From intricate jewelry pieces to large-scale industrial projects, the 300W Laser Welder Machine delivers outstanding results in short time frames.

Whether you are a professional craftsman or just getting started with laser welding, this machine will give you an edge over your competition thanks to its unmatched power and precision. Discover how the 300W Laser Welder Machine can make your next project easier than ever before!

Advantages of the 300W Laser Welder Machine

The 300W Laser Welder Machine is a powerful tool that offers numerous advantages for precision welding. Its advanced technology allows it to make clean, accurate welds with minimal heat distortion or splatter.

This makes it ideal for applications where precise welds are essential, such as in the automotive and aerospace industries. It also has a high-speed pulse system which enables faster welding speeds than traditional welding methods, meaning projects can be completed more quickly and efficiently.

Additionally, its small size means it can fit into tight spaces and reach spots that would otherwise be hard to access with conventional tools. Finally, its low power consumption ensures cost savings over time compared to other welder machines on the market today.

All these features combine to make the 300W Laser Welder Machine an excellent choice for any production line requiring top-quality results at maximum speed.

Exploring Its Power and Precision Capabilities

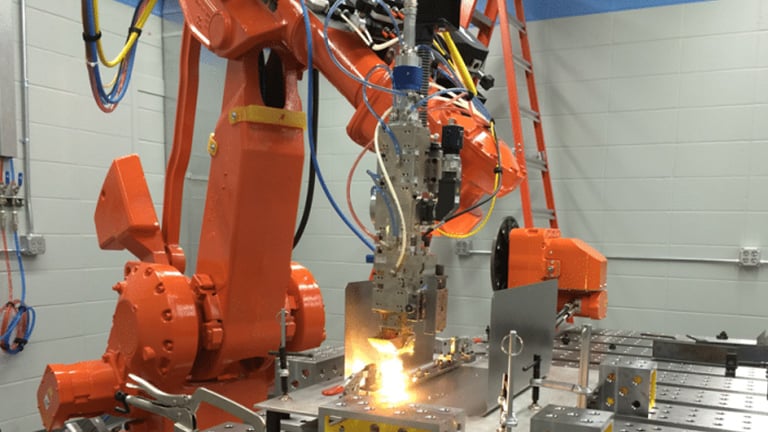

The 300W laser welder machine is a powerful and precise tool that has revolutionized the manufacturing industry. It enables companies to complete their welding projects with unparalleled accuracy, speed, and efficiency.

With its cutting-edge technology, this machine can weld components of any size or complexity in just a matter of minutes. The high-tech design of the 300W laser welder gives it an advantage over other types of welding equipment as it offers precision control for every step in the production process from start to finish.

As such, businesses that rely heavily on welding can maximize their output while reducing costs associated with labor and materials. Additionally, using the 300W laser welder allows manufacturers to reduce turnaround times on jobs significantly due to its ability to quickly switch between different settings for various applications.

Exploring Its Power and Precision Capabilities, the 300W laser welder provides businesses with world-class performance at competitive prices making it one of the most sought-after machines in modern manufacturing industries today.

Safety Considerations for Using the 300W Laser Welder Machine

Safety is a vital consideration when using the 300W Laser Welder Machine. This type of machine can generate powerful and precise laser beams to weld materials, but it also comes with inherent risks.

When operating the 300W Laser Welder Machine, workers must adhere to several safety protocols to prevent injury or damage from occurring. First, workers should always wear protective equipment such as goggles and gloves while working with the welder to protect their eyes and skin from heat or radiation exposure.

Additionally, only those who have adequate training on how to use the machine should be allowed near it at all times; any untrained personnel should be kept away from its vicinity for their safety. Furthermore, a fire extinguisher should always be nearby should sparks fly during welding operations.

It is also important that the workspace remains clean and well-ventilated during welding operations as debris buildup could result in an accident due to obstructing visibility or blocking airflow around the power source of the welder machine itself. In addition, all flammable objects such as paper towels or clothes need to remain far away from work areas where welding will take place; even static electricity generated by movement can cause these items to ignite if they come into contact with hot surfaces of the welder machines parts while it is turned on.

Finally, workers must ensure that no electrical cords are frayed or cracked before plugging them into outlets since this poses a serious risk of electrocution if proper cautionary measures are not taken beforehand!

Conclusion

The 300W Laser Welder Machine is a powerful and precise tool that has revolutionized the welding industry. This machine offers excellent weld quality, cost-effectiveness, and minimal heat input into its workpiece compared to traditional welding methods.

With its adjustable power output and wide range of material settings, the 300W Laser Welder Machine can be used in a variety of applications ranging from jewelry making to automotive repair. It is an essential tool for any shop or facility looking to maximize their welding capabilities with minimum resources.