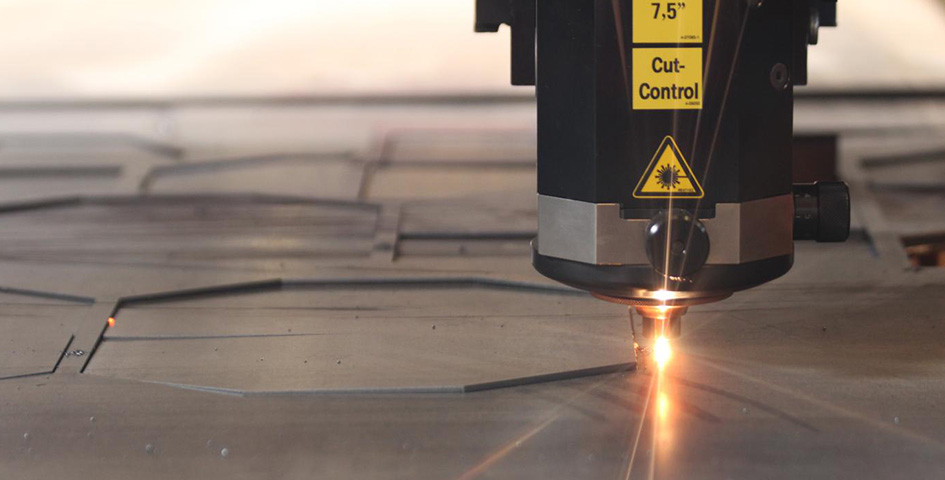

The fabrication industry has been revolutionized by the introduction of fiber laser cutting. This breakthrough technology enables a greater level of precision and accuracy than ever before, allowing for complex components to be made in shorter timeframes with fewer resources.

From sheets to tubes, the versatility of this new method is unmatched, offering an unprecedented level of control over the design process. With its ability to rapidly cut through hard materials such as steel and aluminum, fiber laser cutting offers manufacturers a wide variety of options when it comes to fabricating parts and products.

As well as being able to create intricate designs on thin materials like paper or leather with ease, this innovative tool can also produce large-scale items from thick material without sacrificing quality. The skys the limit when it comes to what you can do with fiber laser cutting – and thats why so many businesses are turning towards it for their fabrication needs!

Introduction to Laser Cutting Technology

Laser cutting technology is revolutionizing the fabrication industry, enabling manufacturers to create complex designs and shapes quickly and accurately. The introduction of fiber laser cutting has enabled fabricators to move from 2D sheet metal parts to 3D tube components in a matter of minutes.

This allows for more innovative product development without sacrificing quality or accuracy. With its ability to cut intricate patterns out of metals such as stainless steel, aluminum, titanium and copper, fiber laser cutting offers unparalleled versatility in terms of design possibilities while maintaining tight tolerances.

As a result, this technology has become highly sought after by industrial fabricators looking for an edge over their competitors. In this article we will take a closer look at how laser cutting works and explore some of the benefits it can bring to your business.

The Benefits of Fiber Laser Cutters

Fiber laser cutting is revolutionizing the fabrication industry and its benefits are becoming more evident every day. With precise cuts, faster speeds, and higher performance than traditional tools, fiber laser cutters offer a wide range of advantages.

Not only can they cut through a variety of materials with ease but they do so in less time compared to other methods. Furthermore, fiber lasers provide excellent edge quality while also reducing the amount of waste produced during production processes. Additionally, their advanced technology allows for greater precision when etching or engraving intricate designs onto sheet material or tubes.

Finally, these machines require minimal maintenance and have long-term cost savings due to their low energy consumption and reduced operational costs. In conclusion, fiber laser cutters offer numerous benefits that make them an ideal choice for any manufacturing operation looking to maximize efficiency and save money over the long haul.

How Fiber Lasers Improve Productivity and Quality

Fiber lasers are revolutionizing the fabrication industry by providing improved productivity and quality in cutting a variety of materials. Thanks to their high power outputs and excellent beam quality, fiber lasers can easily cut through sheets or tubes with very little thermal distortion compared to traditional methods.

Not only do they save time due to faster cutting speeds, but also reduce the amount of energy required for each job – making them more efficient than other systems. In addition, they produce superior edge finishes which means less post-processing is needed for highly accurate parts.

This makes it possible to turn out precision components quickly and cost-effectively without compromising on quality. Fiber laser technology is enabling manufacturers to make better use of their resources while improving overall product performance as well as customer satisfaction levels.

Conclusion

in the paragraph The fiber laser cutting technology is revolutionizing fabrication and has changed the way materials are cut from sheets to tubes. This new method of cutting is faster, more precise and cost-effective than traditional methods.

It also offers a wide range of benefits such as greater accuracy, increased productivity, improved safety and reduced waste generation. With its many advantages over other cutting processes, it’s no surprise that fiber lasers have become so popular with fabricators.

If you’re looking for a better solution for your sheet or tube cutting needs, look no further than fiber laser cutting technology. To learn more about this revolutionary process and how it can benefit your business, contact us today!