There are many myths around prototyping. People often assume that prototypes can be difficult to produce and the huge costs involved in their production makes them impractical. However, this is not true.

Prototyping is the first and fundamental step in the journey of a product to market. It reveals hidden obstacles and unpredicted challenges. It is not right to wait till the manufacturing stage to discover problems in a product.

The prototyping stage thus, makes you understand the difficulties involved, highlights technical and financial constraints and of course gives you a chance to uncover all those errors earlier while saving you the cost of a gem!

What Are The Benefits Of Prototyping Your PCBs?

Here are 10 reasons why prototyping your PCBs is beneficial:

1. Helps Determine The True Cost Of Production

When you create a prototype of a product, you get the first-hand idea of the cost required for its production. You will also get an idea of how much each component of the prototype will cost. This will then also give you an insight of the amount of material needed.

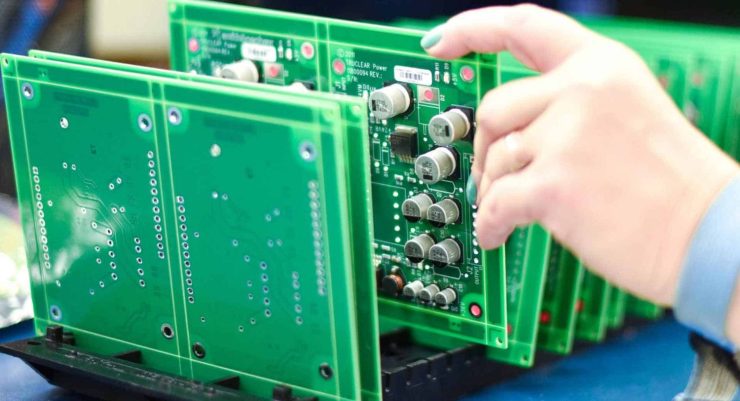

Also, this helps the concerned professionals with quantifying the per unit production cost as well as mass production cost. Outlining the production will initiate the process of actual manufacturing. Once your prototype is ready, you can start with the manufacturing process. You can outsource your manufacturing wework to reputed companies like uetpcb.com.

2. Helps To Review The Efficiency Of Manufacturing Processes

When you start with prototyping your PCBs, you start reviewing and analyzing the product properly. You monitor if the manufacturing processes you are currently relying on are working efficiently or not. You then get a chance to try out different methods.

In this way, you also get a chance to experiment with more economical and easy ways. Also, you get to monitor the design, the functionality, the time of production, the manual effort and the degree of work in the prototyping stage itself.

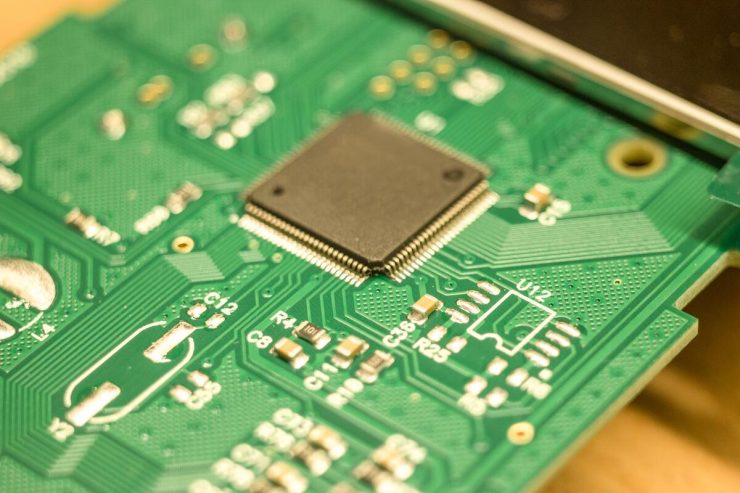

3. Allows You To Test All The Components Individually

The prototyping stage is a must for complex projects. It gives you the ability to test and validate each and every component individually. This will also enable your team to observe any issues or errors that occur in the components separately and also when combined. This makes the process of resolving problems way easier. Also, there will be less work load, less effort, energy and effort.

4. Minimizes Guesswork And Rework

Continuing with the benefits of testing all the components individually, prototyping your PCBs also eliminates the guesswork from the entire equation. Your design teams also get to identify problems quickly and accurately. This reduces the chance of errors to a larger degree and prevents you from rework as well. Once you are done testing boards before full production, you are all set to go.

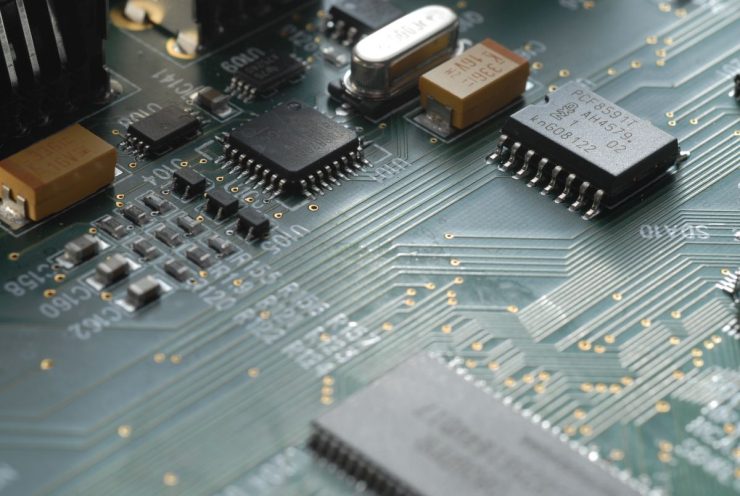

5. Helps To Adjusts Design, Colors And Quality

When your design is on paper or on a screen, the problems in it are not always noticeable. Therefore, by creating a prototype of your PCB, you hold your design, your imagination in real life and find if it actually turned out the way you wanted. Also, this is the chance to obtain feedback either from the client itself or any third-party. You also get a chance to adjust the color, shape and texture of your prototype. At this stage you are more equipped to make it more marketable.

6. Helps To Check Tolerance And Durability

Prototyping your PCB, enables you to be in a position to test your product for any structural weakness. If they exist, then it can affect the functionality and durability. So, you can fix the problem immediately and ensure the durability of the product as well. This will also help you in controlling downstream discovery and repairing costs.

7. Helps Improve Efficiency

By testing the PCB prototype, you can find all the issues and flaws in your product. You can also take assistance from quality assurance methods and standards before you roll out for full production. Without it, discovering the causes of inadequate performance would be a time-consuming process. Prototyping increases your efficiency and cuts down on damage costs of your product.

8. Helps Resolve Conflicts

When an entire team works together to bring a design into life, there are chances of disagreements and conflicts. Each person has a different opinion, idea and expertise. So, when you use a PCB prototyping, it allows you to witness which features worked best and which did not. Concluding, on a final discussion will optimize the design and result in the best possible product.

9. Gives An Idea Of How The Future Product Is Going To Look Like

Prototyping a product gives the idea of how the future product is going to look like. You can also make the prototype available to a bunch of sample users. This will help you determine whether the interaction with the product is comfortable or not and if it is meeting the expectations or not. Remember to give enough time for doing this. If there are any errors by chance, you can take care of it before the official launch.

10. Helps You To Market Your Product Better

Another advantage of prototyping your PCB is that you can use it to attract more customers that can invest in your product before you start budgeting for the actual implementation. This will aid you financially and also help you in networking with people from different strata. You start to promote it way before its official launch so that the market and the customers are ready to embrace it.

Conclusion

Having a prototype makes it easier for your team to understand the exact areas they need to work on. It also gives you the opportunity of better and practical planning to achieve the desired results and to determine the accurate cost of the work.

The benefits of prototyping also include reduced timeline, workload, cost, effort, risk and time. The feedback that comes from testing is also of utmost value and only adds to making the product better. On that note, industry professionals also suggest prototyping is the best way to measure where you stand and how much you need to work on.